Electric motor starters help power up many applications, so troubleshooting different motor starter types is an important skillset. If you’ve had electric motor starter problems, you know they’re the “ignition switch” that kickstarts electric motors into motion. When you know motor starter types and troubleshooting, you can fix or replace motor starters for smooth, controlled motor operation.

Electric motor starters not only initiate and control electric motor operations. They’re the interface between the power supply and the motor, supporting a systematic, safe motor startup process. You don’t want operators to get hurt, and you don’t want equipment damaged by electrical surges or fire. In this post, we’ll demystify electric motor starters, breaking down their types, functions, and troubleshooting methods. Let’s dive in!

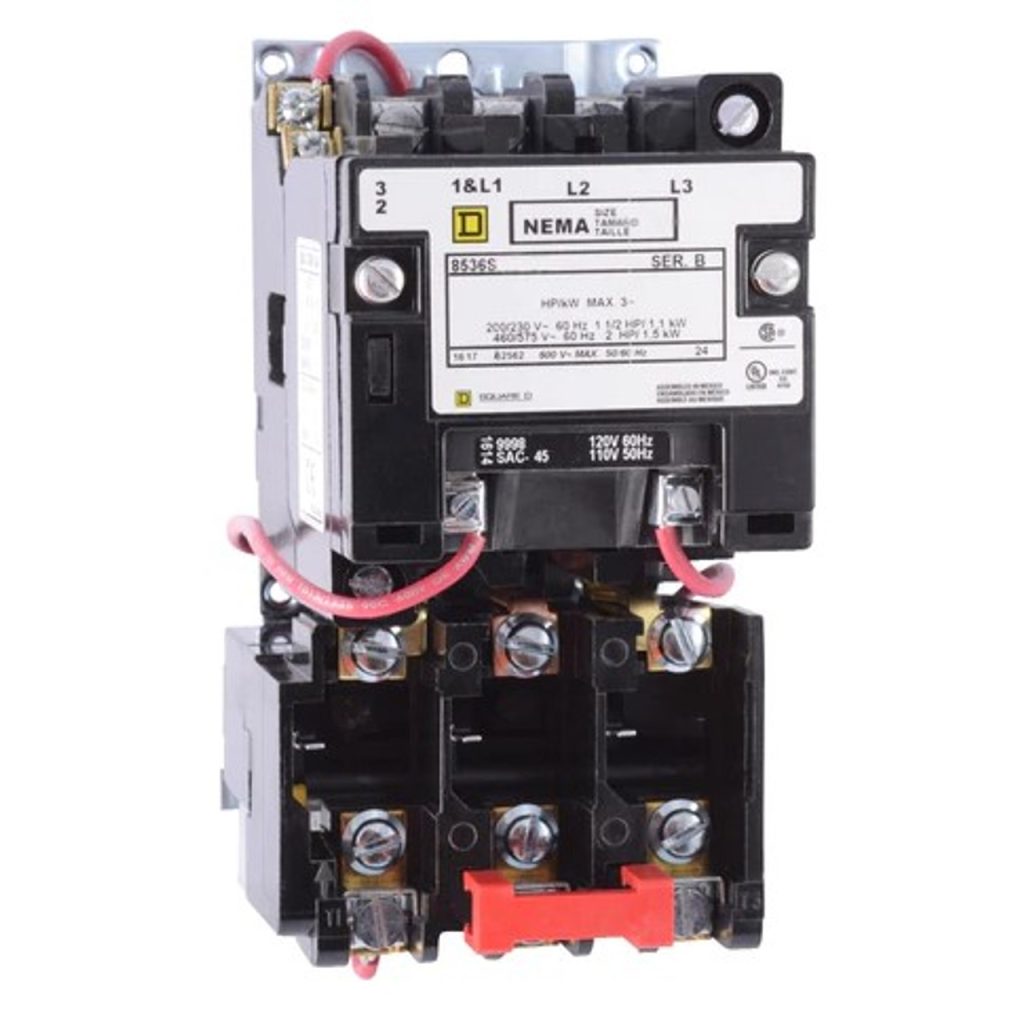

Need Replacement Motor Starters?

Get Starter QuoteCommon Types of Electric Motor Starters

Introducing the primary motor starter types—Direct-On-Line (DOL), Star-Delta, and Soft Starters—these three are among the most common in electric motor operations. DOL starters, like a simple on/off switch, provide an instant, full-power connection designed for uncomplicated systems. Star-Delta starters, similar to a two-step ignition, reduce motor stress during startup by initially connecting in a low-power configuration, gradually increasing to full power. Soft starters act as a gentle on-ramp, gradually increasing power to prevent sudden motor acceleration.

In the table below, we describe these popular starters and add several more, including a typical application:

| Common Electric Motor Starters | Description | Application |

| Direct-On-Line (DOL) Starters | During startup, DOL starters supply full voltage to the motor terminals. They are simple and inexpensive, which may result in a large starting current. | Good for small to medium-sized motors where high starting current is acceptable. |

| Star-Delta Starters | The motor in this starter begins in a star configuration (low voltage) and then switches to a delta configuration (full voltage) over a certain time. The initial current is reduced as a result. | For large motors where a high starting current may cause voltage dips. |

| Autotransformer Starters | An autotransformer is used in autotransformer starters to lower the voltage during startup, thus decreasing the beginning current. Once the motor is going, the voltage is raised. | Designed for medium-sized motors where a reduction in starting current is called for. |

| Soft Starters | Soft starters gradually boost the voltage and current to the motor during startup. This decreases mechanical stress and electrical disturbances. | For applications requiring smooth acceleration and reduced wear on mechanical components. |

| Variable Frequency Drives (VFD) | They can work as starters. VFDs regulate motor speed by altering the frequency and voltage of the electricity provided. They’re efficient and provide precise control over motor speed. | Meant for applications needing variable speed control, like pumps, fans, and conveyor systems. |

| Electronic Motor Starters | These starters use electronic components to control the motor’s startup and operation, providing features like overload protection and soft starting. | Used in modern and advanced motor control systems. |

Electric Motor Starter Problems and Possible Causes

Failing to Start

Issue: The motor doesn’t initiate when the starter is activated.

Possible Causes: Faulty wiring, a defective starter switch, or a malfunctioning motor.

Tripping Circuit Breakers

Issue: The circuit breaker frequently trips when attempting to start the motor.

Possible Causes: Overloaded circuits, short circuits, or issues within the motor windings.

Excessive Motor Heating

Issue: The motor becomes excessively hot during operation.

Possible Causes: Overloading, insufficient ventilation, or issues with the motor’s cooling system.

Unusual Noises During Startup

Issue: Strange sounds, such as grinding or clanking, are heard during the motor’s initiation.

Possible Causes: Misalignment, worn-out bearings, or mechanical issues within the motor.

Inconsistent Motor Speed

Issue: The motor operates at varying speeds, impacting performance.

Possible Causes: Voltage fluctuations, issues with the power supply, or problems with the motor’s internal components.

Frequent Starter Burnouts

Issue: The starter components, such as relays or contactors, burn out regularly.

Possible Causes: Overloading, electrical surges, or poor-quality starter components.

Starter Continuously Running

Issue: The starter remains engaged even after the motor is running.

Possible Causes: Stuck contacts, a malfunctioning control circuit, or a defective starter switch.

Uneven Motor Operation

Issue: The motor exhibits irregular or jerky movements during startup.

Possible Causes: Mechanical obstructions, misalignment, or issues with the load on the motor.

Intermittent Starter Failures

Issue: The starter works inconsistently, sometimes failing to start the motor.

Possible Causes: Loose connections, wiring issues, or intermittent faults in the control system.

Excessive Vibrations

Issue: Unusual vibrations occur during motor operation.

Possible Causes: Misalignment, imbalanced loads, or problems with the motor’s bearings.

Understanding these common starter issues gives you a starting point for troubleshooting, identifying, and fixing motor startup problems.

Quick Reference: Motors Starter Issues, Causes and Basic Troubleshooting Steps

| Motor Starter Issues | Possible Causes | Troubleshooting Steps |

| Failure to Start | – Faulty wiring – Defective starter switch – Motor issues | – Check for loose or damaged wiring connections – Test the starter switch for functionality – Verify the motor’s condition by testing it separately |

| Tripping Circuit Breakers | – Overloaded circuits – Short circuits – Motor winding issues | – Identify and rectify any overloaded circuits – Inspect for and fix any short circuits in the wiring – Examine the motor windings for potential issues |

| Excessive Motor Heating | – Insufficient ventilation – Overloading – Cooling system issues | – Ensure proper ventilation around the motor – Check for overloading conditions to reduce load – Inspect the motor’s cooling system for malfunctions |

| Unusual Noises During Startup | – Misalignment – Worn-out bearings – Mechanical issues | – Investigate for misalignment issues in the motor – Inspect bearings for wear and replace if needed – Check for any mechanical issues within the motor |

| Inconsistent Motor Speed | – Voltage fluctuations – Power supply issues – Internal component problems | – Stabilize power supply to reduce voltage fluctuations – Investigate and resolve issues with electrical system – Inspect, replace faulty internal motor components |

| Frequent Starter Burnouts | – Overloading – Electrical surges – Poor quality components | – Ensure the motor is not overloaded – Invest in high-quality starter components – Install surge protectors to avoid electrical surges |

| Starter Continuously Running | – Stuck contacts – Malfunctioning circuit – Defective starter switch | – Check for stuck contacts in the starter – Inspect the control circuit for malfunctions – Test and replace a defective starter switch |

| Uneven Motor Operation | – Mechanical obstructions – Misalignment – Load issues | – Inspect for mechanical obstructions near motor – Align motor properly if misalignment is detected – Adjust the load to ensure it’s evenly distributed |

| Intermittent Starter Failures | – Loose connections – Wiring issues – Control system faults | – Tighten wiring connections – Inspect the wiring for any signs of damage or wear – Use diagnostic tools to identify intermittent faults |

| Excessive Vibrations | – Misalignment – Imbalanced loads – Worn bearings | – Check for misalignment issues and realign – Balance the loads to ensure even distribution – Inspect, replace worn bearings causing vibrations |

What You Should Know About Motor Starters and Troubleshooting

We’ve navigated the basics of electric motor starters. From understanding their crucial role as the ignition switch powering applications to exploring technical topics like starter failures, electric motor starter replacement and troubleshooting.

You now should understand the importance of a smooth and safe motor startup process. We demystified types of starters, from the straightforward Direct-On-Line to the stress-reducing Star-Delta and the gradual powering-up using a Soft Starter.

Like most of us, you’re likely not an expert on all starter types, but you should feel confident speaking with a trained expert about your particular electrical motor and starter requirements.