Circuit breakers work to interrupt current flow to protect electrical circuits from excess currents. They function like an on-and-off switch, except they operate manually.

Since their invention in 1879 by Thomas Edison, electrical circuits have become a major part of our everyday lives. Found in every building, many electrical companies manufacture them, such as Cutler-Hammer and General Electric. Numerous types of circuit breakers exist on the market, including thermal magnetic ones like the TFK236F000.

Thermal Magnetic Circuit Breakers

Thermal magnetic circuit breakers have the fastest speed of interruption compared to other types of breakers, like hydraulic-magnetic circuit breakers. They can interrupt a current flow within a circuit in as little as 4 milliseconds. Because of this feature, thermal magnetic circuit breakers are commonly used in applications where a quick response to a short circuit current is needed.

Practical real-life applications of thermal magnetic circuit breakers include places where high precision performance is required, such in a distribution board. This makes them a popular choice in telecommunications, process control and industrial applications.

Switching Mechanisms

Thermal electric circuit breakers get their name from the two switching mechanisms inside the breaker. One of the mechanisms is a bimetal switch, and the other mechanism is an electromagnetic switch.

Each switch interrupts a different type of electrical fault. The electromagnet switch can respond instantaneously to short circuits, which are large surges in the current. The bimetallic strip, on the other hand, responds to less extreme short circuits that continue for extended periods of time.

Bimetallic Switch

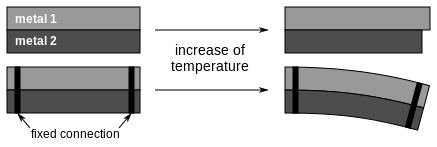

Bimetallic strips can convert a temperature change into a physical movement. This occurs by expanding two different strips of metal at different rates using heat. The two metal combinations in this process are usually steel and copper or steel and brass. They are joined together along their length by methods such as welding or riveting.

In a thermal magnetic circuit breaker, the bimetallic strip is placed behind a trip bar that is connected to the current pathway. Any electrical current passing through the pathway that exceeds the breaker limits will heat the bimetallic strip, causing it to bend.

However, the bimetallic strip can tolerate small over-currents across longer periods of time. Eventually, the over-currents will cause the bimetallic strip to bend and touch the trip bar, effectively halting the current.

Due to the presence of this bimetallic strip, thermal magnetic circuit breakers are highly sensitive to external temperatures. This means if you operate a thermal magnetic circuit breaker in an extremely hot environment, they will trip the circuit earlier than intended. This is because the extra heat can activate the bimetallic switch before its threshold value.

Electromagnets

The electromagnetic component of a thermal electric circuit breaker consists of an electromagnet. A flowing electrical current produces a magnetic field around these electromagnets. This magnetic field is not permanent and will disappear when the current stops flowing.

One of the main components of an electromagnet is an insulated wire that wraps around a coil. The electrical current responsible for creating the magnetic field flows through this coil. The magnetic field from the current is in the center of the coil. The maintenance of the electrical current and magnetic field requires a constant supply of power.

Electromagnetic Switch

The electromagnet inside thermal magnetic circuit breakers responds to varying levels of electrical currents. Elevated levels of currents generate a magnetic field that is strong enough to attract nearby armature. This armature then moves closer to the electromagnet and trips the breaker, effectively stopping the current flow.

The trip process due to the armature is almost instantaneous because of the fast speed at which electromagnetic induction occurs. As a result, sudden loads in the circuit cause large spikes in current, such as switching on a motor, and can potentially trip the circuit without delay.

Amperage Ratings

Amperes, also known as amps, is a base SI unit to measure electrical current. Electrical devices with greater amperage ratings mean they can handle more electron flow.

Like most electrical devices, thermal magnetic circuit breakers have various rated currents. For example, a 400-amp thermal magnetic circuit breaker, such as the TJK436F000, will trip when the current reaches 400 amperes. This makes them ideal for equipment that has similar current carrying capacities. A 600-amp thermal magnetic circuit breaker, like the TJK636F000, on the other hand, should only be used with equipment that can handle around 600 amps of current.